rockwell and brinell hardness test ppt|disadvantages of rockwell hardness test : consultant Rockwell hardness testing can detect variations in case hardness and decarburization of case hardened parts. Testing can also be done at elevated temperatures . Resultado da 5 de fev. de 2024 · StreamM4u: Has an excellent filter for easy streamlining of movies. Moviesjoy: It offers videos in 1080 HD and is very fast, ensuring the most enjoyable experience. Vudu offers free and pay-per-view options and easy access to thousands of movies and shows. SpaceMov: One of the .

{plog:ftitle_list}

novinha magrinha faz gang bang na rua e leva banho de leite. 5 min. marido me pega com outro homem na nossa cama e participa da brincadeira. 10 min. Perdendo a virgindade do cuzinho no swing. 4k. 15 min. Meu marido me pegou dando minha buceta e gravou tudo. 16 min. Putinha de vestido vermelho dando pra 2.

Rockwell hardness testing can detect variations in case hardness and decarburization of case hardened parts. Testing can also be done at elevated temperatures .Rockwell hardness testing involves indenting a material with either a .

The document discusses different hardness testing methods including Brinell .The results were as table 1. The Charpy impact test determines the impact . Rockwell hardness testing involves indenting a material with either a diamond or steel ball indenter under a minor preload and then a major load. The difference in indentation depth is used to determine the Rockwell .

The document discusses different hardness testing methods including Brinell hardness testing and Rockwell hardness testing. Brinell hardness testing involves .Brinell Hardness Test Standard loads range between 500 and 3000 kg in 500-kg increments; during a test, The load is maintained constant for a specified time (between 10 and 30 s). .Key Words: Hardness Testing, Brinell, Vickers, Rockwell, Mechanical Properties. Type of Module: PowerPoint presentation with lab or in-class demonstration depending on .

The Rockwell hardness test measures the hardness of a material by applying two loads to a diamond or steel ball indenter that is pressed into the surface of the material. The hardness number is determined using the formula HR = E - e, . Hardness scale + Brinell + Vickers + Shore + Rockwell • Hardness is a property of a material in the solid phase that give it high resistance to various kinds of shape change when force is applied. Rockwell Standards Tests. Brinell Hardness Test • Brinell hardness is determined by forcing a hard steel or carbide sphere of a specified diameter (2.5mm) under a specified load into the surface of a material and .

The results were as table 1. The Charpy impact test determines the impact toughness or strength of a material by measuring the energy absorbed when a pendulum strikes a V-notched specimen. Testing was .

rockwell vs brinell hardness test

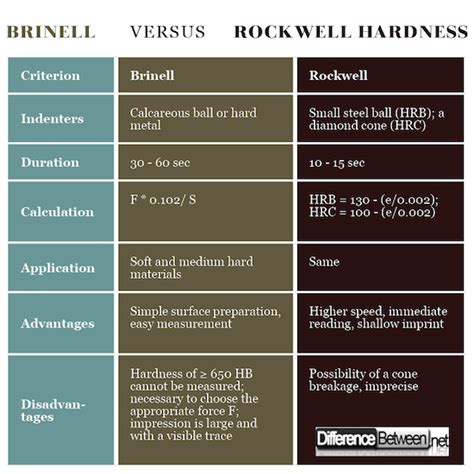

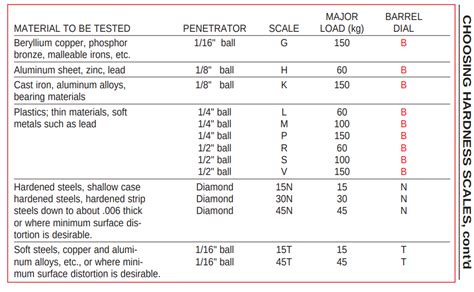

Brinell hardness testing involves indenting a sample with a hardened steel ball under a load and measuring the indentation diameter. Rockwell hardness testing uses different indenters and loads to make indentations of varying .Duration of Brinell and Rockwell Hardness; The Brinell test is very slow (30 – 60sec). Rockwell’s test is shorter (10 – 15sec). Calculation of Brinell and Rockwell Hardness; Brinell’s Hardness (HB) is the ratio of the applied force F (N) and the surface of the fingerprint S (mm 2): HBW = (F*0.102/ S); S = π* D* h. 12. Working Principle 1. SELECTING THE HEAD AND TEST BLOCK Hardened steel and hard alloys like Cast Iron were tested in the Rockwell C scale, using a diamond cone as head and a 150 kg major load. .Superficial Rockwell hardness test: In this test, a load of 15, 30, or 45 kg is applied to the surface of the material for a few seconds, depending on the hardness of the material. Rockwell hardness test for plastics: In this test, a .

9. VICKERS HARDNESS TESTING M FACTS The Vickers hardness test uses a square-base diamond pyramid as the indenter. This test is preferable to the Brinell test where hard materials are concerned, as it uses a diamond indenter. The included angle between opposite faces of the pyramid is 136° The loads ordinarily used with this test range from 1 to .This eLearning course focuses on Rockwell and Brinell hardness testing and Vickers and Knoop microhardness testing. Participants will learn about how the tests are performed, test sample requirements, test parameter selection, and testing requirements. The course can be completed in 30 minutes.

Brinell Hardness Testing Method - Download as a PDF or view online for free. . Vickers (7) Mohs Hardness (4)Barcol Hardness Brinell Hardness The Rockwell Hardness test is a hardness measurement based on the net increase in depth of impression as a load is applied. Hardness numbers have no units & are commonly given in the R, L, M, E and K .

This article explains the procedure to perform the Rockwell hardness test on metals. Rockwell Hardness Test Procedure. The Rockwell hardness test employs the principle of differential-depth method. During the test, the indenter of the equipment is forced to make a residual depth on the test specimen. Diagram of Brinell Hardness Testing Machine. Brinell Hardness Test is one of the most important hardness tests in the engineering industry and metallurgy. It is used when the surface of the metal is very rough to use another hardness test on it. There are two methods to perform the Brinell hardness Test on the metal as follows: Standard Method . There are several common hardness tests used to measure this property, including Brinell hardness testing, Rockwell hardness testing, and Vickers hardness testing. Brinell hardness testing involves indenting a material's surface with a hard steel or tungsten carbide ball under a heavy load and measuring the diameter of the indentation. The .These approximate relationships between hardness and tensile strength do not apply to nonferrous metals, with the possible exception of certain aluminum alloys. Related: Brinell Hardness Testing Equation. Table A Brinell Hardness to .

The document provides information about different hardness tests for materials, including Brinell hardness test, Rockwell hardness test, and Vickers hardness test. It explains how each test is conducted, the equipment used, factors that influence the measurements, advantages and disadvantages of the tests.Hardness is the property of a material that enables it to resist plastic deformation, usually by penetration. However, the term hardness may also refer to resistance to bending, scratching, abrasion or cutting.The Brinell hardness test (HBW) serves as a crucial scale for quantifying material hardness, defined in ASTM E10 and BS EN ISO 6506-1 standards. . Rockwell hardness testing is performed with an indenter of a specified size applied with a specified force for a fixed amount of time. A small Tungsten steel ball (HRBW method) is used to penetrate .Theory: Rockwell Hardness Test Use of specific load and indenters to measure how deeply an indenter penetrates into material under load. This penetration depth is used to determine materials hardness on defined scale. HRC- Diamond cone indenter,150kgf major load. Suitable for harder material. The Machine consist of frame and base, indenter, load application system, .

The diameter of the indentation left in the test material is measured with a low powered microscope. The diameter of the impression is the average of two readings at right angles. Brinell hardness number table can simplify the . The Rockwell hardness test involves applying a sequence of loads to the material and measuring the depth of the resulting indentation, which indicates the material’s hardness. . Brinell Hardness Test. The Brinell hardness test is ideal for measuring the hardness of metals with coarse or inhomogeneous grain structures, such as cast iron and .

Hardness tests of metals are essential to manufacture reliable big machines and automobiles. The hardness test should be first selected according to the needs of the material. You can find answers to questions about the Brinell and Rockwell in the article, as we have clarified the difference between the two tests. Brinell Hardness. Relatively high loads are applied to parts via a tungsten carbide ball in this method. Unlike with Rockwell testing, Brinell tests measure the diameter of the indentation made by the ball, not the depth. A 10mm ball with an applied load of 3,000 kgf is most common for Brinell testing. Brinell tests are ideal for castings and . Hardness - Download as a PDF or view online for free. 13. • 1822: Friedrich Mohs (Ger) - A ten-point scratch hardness Mohs scale. • 1900: J. A. Brinell (Swe) - A ball indentation / dent dia size Brinell Hardness. • 1920: S. R. Rockwell (US) – Minor, major load / dent depth Rockwell Hardness. • 1925: R. Smith and G. Sandland (Eng) – Diamond pyramid indenter / . Rockwell Hardness test A sphere – conical diamond cone of 120º angle and a spherical apex of radius 0.2 mm is used Depth of indentation t is measured. Gradually applied load, Load is applied at right angle to the specimen surface. R = 100 – 500 × t Depending on the load used a scale A, B, C, etc. used. Rockwell test should not be used on .

2. Brinell hardness test Brinell Balls Table 1 dia and tolerance of Brinell hardness ball Sr. no Ball dia, mm Tolerance, mm 1 10 ±0.005 2 5 ±0004 3 2.5 ±0.003 4 2 ±0.003 5 1 ±0.003 Measuring Device The divisions of the micro meter scale of the microscope or other measuring devices used for the measurement of the diameter of the indentations shall be such .Manufacturing started in 1920 by Charles Wilson. Wilson revised the . – A free PowerPoint PPT presentation (displayed as an HTML5 slide show) on PowerShow.com - id: 26c836-ZDc1Z . Limitations of the Brinell Hardness Test. a) Sample must be ten times thicker than the indentation depth (sample usually should be at . Rockwell Hardness Test.

To wrap up, knowing the best-suited hardness test of the three, Rockwell, Brinell, and Vickers, for your hardness test will require that you understand the determining criteria for employing any hardness test. In the final analysis, the type of material and the environment where the test will take place will significantly determine the best . Basic principle and practical procedure of the Brinell hardness test - Testing machine - Test piece - Spherical indenter - Basic principle - Definition .Brinell hardness test is one of the indentation hardness tests developed for hardness testing. In Brinell tests, a hard, spherical indenter is forced under a specific load into the surface of the metal to be tested. . Common indentation hardness scales are Brinell, Rockwell and Vickers. See also: HardnessSCOPE. The Brinell hardness test is an empirical indentation hardness test that can provide useful information about metallic materials. This information may correlate to tensile strength, wear resistance, ductility, and other physical characteristics of metallic materials, and may be useful in quality control and selection of materials.

With the Brinell hardness test, a carbide ball is pressed into the material. The indentation surface serves as a measure of the hardness. Vickers hardness te.

disadvantages of rockwell hardness test

2023. 2025. A Final da Copa Libertadores da América de 2024 será a 65ª decisão do principal torneio continental de futebol da América do Sul, organizado anualmente pela .

rockwell and brinell hardness test ppt|disadvantages of rockwell hardness test